Flat roofs differ significantly from slanted roofs. They contain more water, conserve more heat, and, to a great extent, remain in place by depending on surface materials. As a result, several building owners have been informed about roof coating and are left wondering whether it is a real solution or just another quick fix. To get a proper response to that, it is better to understand how roof coating actually works, how it interacts with flat roofing systems, and what its boundaries are.

Key Takeaways

- Roof coatings help protect flat roofs by reducing damage from sunlight, moisture, and temperature changes.

- They are designed to extend roof lifespan, not replace roofing systems or fix structural problems.

- Silicone, acrylic, and elastomeric coatings each perform best under different roof conditions.

- Proper surface preparation is essential for coating performance and durability.

- Roof coatings work best as part of a planned maintenance approach rather than a temporary fix.

What are Roof Coatings?

Roof coatings are liquid-applied products applied over an existing flat roof surface. After they are cured, they form a continuous protective covering that adheres to the roof beneath.

Coatings on the roof provide protection. They are placed on an existing roof structure to slow wear caused by sunlight, moisture, and temperature changes. They are not a new roof. They are not installed as insulation, decking, or for badly damaged membranes. In cases of deep structural issues with a flat roof, a coating will not fix them.

They can contrast with membranes or replacements. Stone roof membranes are placed as the base waterproofing measure. Coatings, on the other hand, are applied to an existing system to increase its service life. Their application is limited to situations in which the underlying roof is stable and intact.

Why Flat Roofs Are Good for Coatings

Water pooling is a major issue. The reason is that flat roofs fail to shed water as quickly as slanted roofs, allowing moisture to remain on the surface for too long. Some coatings can withstand this exposure compared to bare membranes.

Another cause is the UV exposure. Flat roofs are constantly exposed to the sun, which will wear down the roofing materials over time. Coatings help absorb or reflect that radiation, thereby causing less surface damage.

Thermal movement also contributes to it. Flat roofing materials swell when hot and contract when it is cold. In the long run, this movement puts a strain on joints and seams. Flexibility and minimization of surface cracking can be achieved through coating.

Lastly, the weak points include seams and penetrations. This is done through a coating that forms a continuous layer, strengthening these sensitive areas rather than exposing them.

How Roof Coatings Actually Work

When used properly, a coating bonds a layer to the existing roof surface through chemical or mechanical means. It is this bond that enables the coating to travel with the roof rather than fall off.

When bonded, the coating seals smaller cracks, including hairline cracks and other small cracks. This sealing effect minimizes the avenues through which water may enter and slows leaks caused by surface wear.

Numerous coatings are also reflective. They reflect some of the sun’s heat, thereby reducing the surface temperature. Less heat will cause less expansion and contraction of the material, thereby reducing fatigue.

Of greatest importance, the coatings delay the degradation of materials. Rather than the UV rays and moisture attacking the initial roof membrane, they initially hit the coating layer. Over time, the roof does not wear, but the coating does.

Types of Roof Coatings Used on Flat Roofs

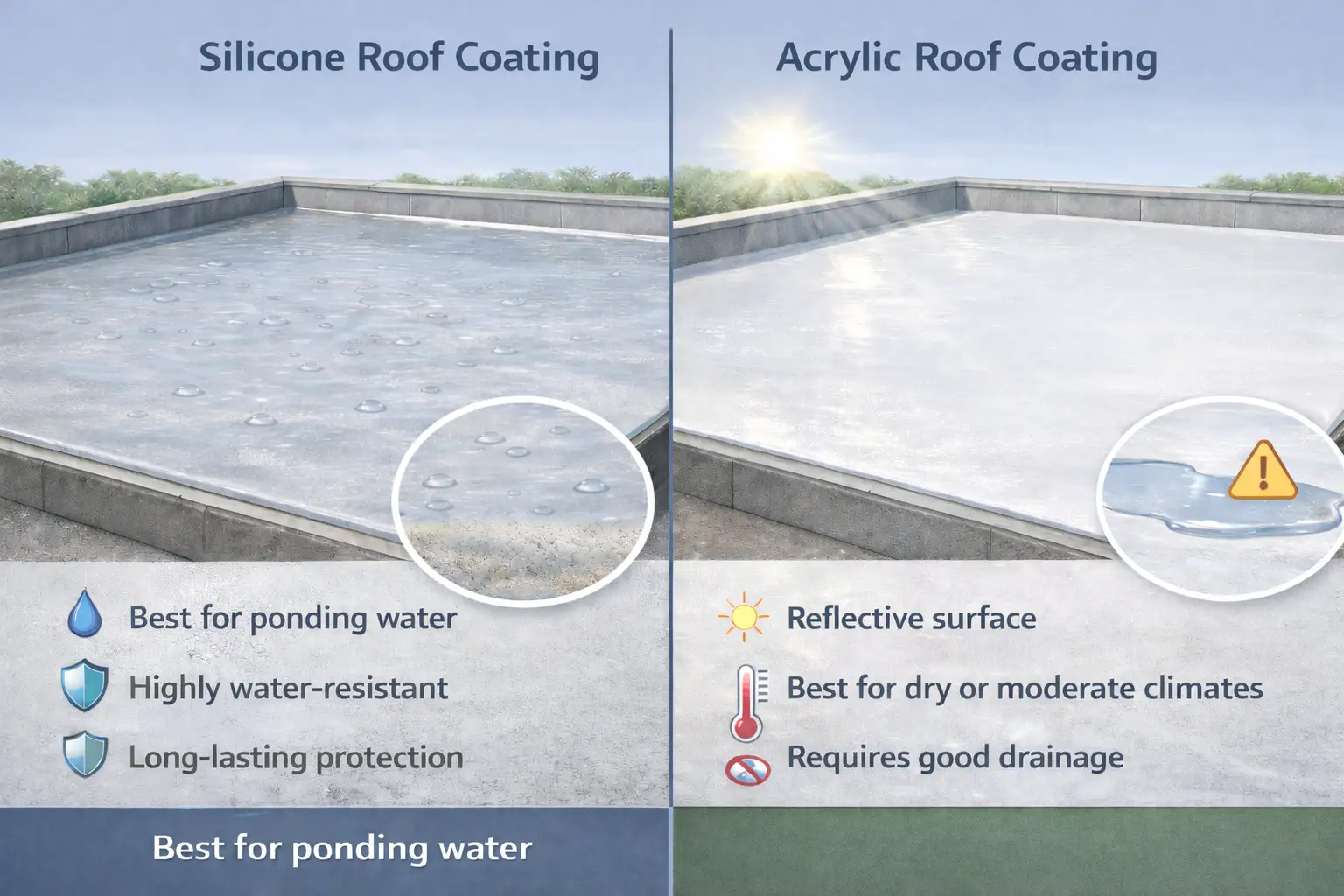

Silicone Roof Coatings

Silicone coatings are used where ponding water is present. They provide longer-lasting moisture exposure than most other systems.

They are strong, water-resistant, and long-lasting. However, they will accumulate dirt over time, and therefore their reflectivity will decrease unless they are wiped. Silicone materials are useful during repair or recoating.

Acrylic Roof Coatings

Acrylic coats are water-resistant and have been claimed to be reflective. They do fairly well in moderately rainy and well-drained climates.

But they cannot resist standing water. They may require more frequent or thicker applications in these types of environments.

Elastomeric and Other Systems

The elastomeric coatings are appreciated for their ability to stretch and recover. This is because of the flexibility in dealing with both the expansion and contraction of flat roofs.

They are commonly applied to numerous types of roofs and are particularly useful where movement is an issue. Their efficiency is very sensitive to surface preparation and the proper thickness of the application.

Key Benefits of Roof Coatings

- An extended lifespan for the roof is one such advantage. Coatings will remove the necessity to repair or replace the current system by protecting it.

- Reflective roof coatings tend to lower surface temperatures. This can reduce thermal stress on the roof materials.

- The level of maintenance can be reduced, as the surface is better protected against UV damage and small cracks.

- There is also cost avoidance. Coatings may help defer substantial capital expenditure, but do not replace the structural work required.

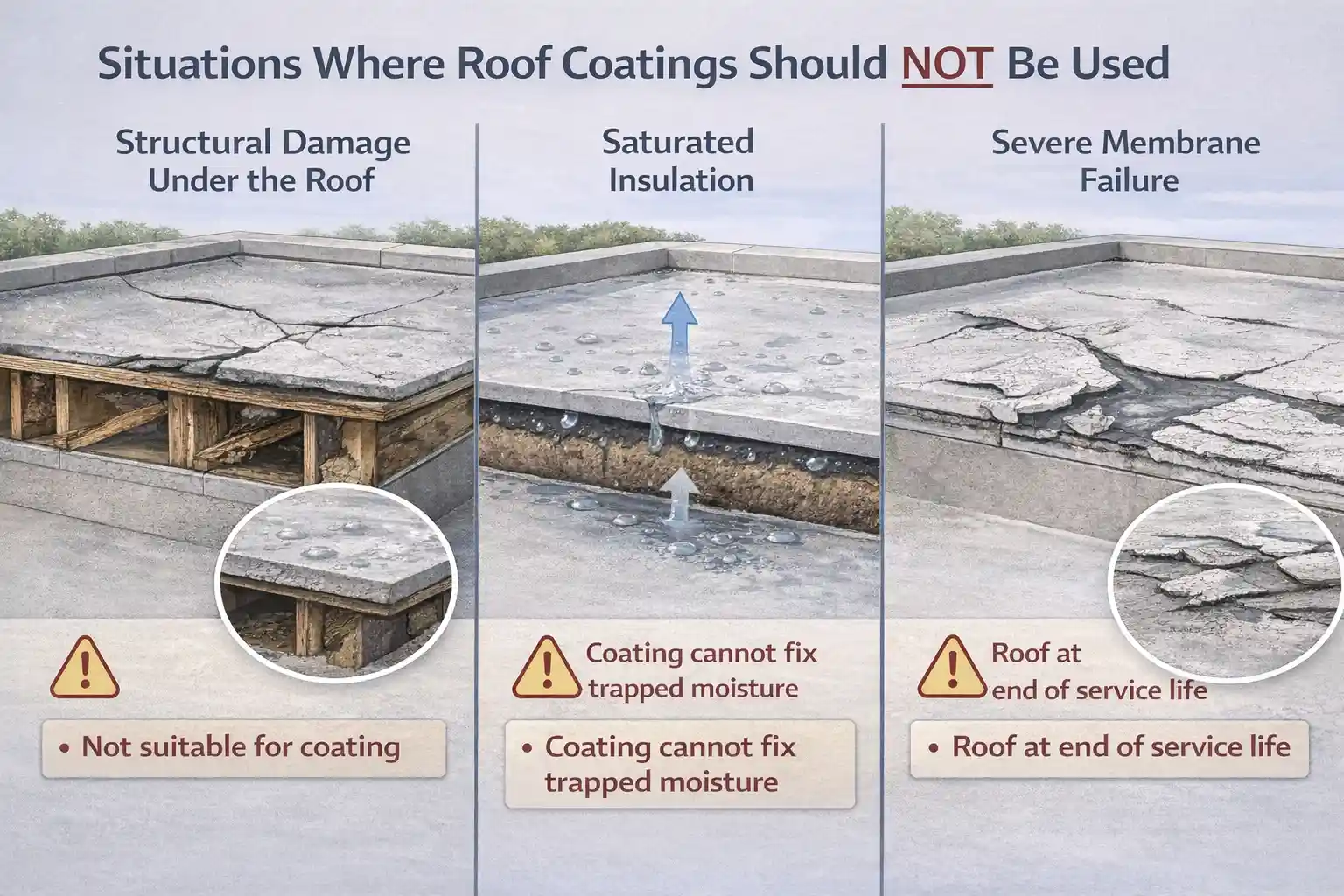

When Roof Coatings Are NOT the Right Solution

- When the structure is damaged underneath, it is not suitable to have a roof coating. The first issue to address is rotten decking or broken framing.

- Another red flag is saturated insulation. Any water under the membrane is impossible to resolve with a coating and can easily lead to failure.

- Extensive splitting or separation generally indicates that the roof is at the end of its service life. In such situations, coats are often abused and disintegrate prematurely.

How Long Roof Coatings Typically Last

The majority of roof coatings have a lifespan of a few years, depending on the material, environment, and maintenance. Finishes are commonly subject to regular inspection and performance that requires periodic paint additions. Recoating cycles are normal and part of the design of such systems for long-term use.

Roof coating for flat roofs serves as a protective layer designed to reduce surface wear, and understanding how these systems perform under recognized roof coating performance standards helps building owners make realistic decisions that support long-term roof reliability.

Final Thoughts

Roof coatings can be a practical way to protect flat roofing systems when used under the right conditions. They are not designed to replace a roof or correct structural problems, but they can slow surface deterioration and extend the usable life of an existing system.

Understanding how coatings interact with flat roofs is essential before making a decision. When applied to a properly prepared stable roof, coatings can reduce exposure to sunlight, limit moisture penetration, and help manage long-term wear. Choosing the right coating approach often depends on the type of roofing system in place, which is further explained in this comparison of modified bitumen vs TPO roofing. However, when underlying damage is present, coatings often fail prematurely, creating false expectations.

Flat roof coatings work best as part of a planned maintenance strategy rather than as a last-minute solution. With realistic expectations and proper evaluation, they can serve as a useful protective layer that supports roof performance over time.

Frequently Asked Questions

Are roof coatings the same as a new roof

No. Roof coatings are applied over an existing roofing system to protect it. They do not replace membranes, insulation, decking, or structural components.

Can roof coatings stop active leaks?

Roof coatings can seal small surface cracks but are not intended to repair active or structural leaks. Any underlying damage should be repaired before application.

Do flat roofs need special preparation before coating

Yes. The roof surface must be cleaned, dried, and repaired. Poor preparation often leads to coating failure.

How long does a roof coating last

Most coatings last several years, depending on material type, climate exposure, and maintenance. Recoating is a normal part of long-term use.

Can roof coatings handle standing water

Some systems, such as silicone coatings, perform better in areas with ponding water. Other coatings may break down if water remains on the surface.

Are roof coatings suitable for all flat roofs?

No. Roofs with saturated insulation, structural damage, or extensive membrane failure are not suitable candidates.

Do roof coatings reduce heat buildup?

Many coatings are reflective and can reduce surface temperatures, potentially lowering thermal stress on roofing materials.